In accordance with our social mission to “Never Stop Testing”, we are strengthening our BCP measures so that our operations can continue even in the event of a disaster. As a result, the Laboratory and R&D buildings are able to continue operations for three days (72 hours) even after a major earthquake.

Power: Emergency generators

Two 3,750kVA large-scale emergency generators installed

Water storage: Laboratory Building water tank

Large-capacity water storage tank (600 tons)

Large-capacity drainage tanks, well water facilities, etc. installed

A seismic base isolation structure is a mechanism that reduces the shaking of the building itself by installing a seismic base isolator between the building and the ground. It is renowned for its use in earthquake resistance, enabling only minor repairs even when an earthquake with a seismic intensity of 7 hit the area.

The facility’s safety is a top priority, built to 1.25 times standard values. The quake resistance is equivalent to that of Class II buildings , as outlined in the Comprehensive Seismic Planning Standards for Government Facilities.

The H.U. Group has established a management system to comply with laws and regulations and prevent the spread of infectious diseases. Measures are taken to ensure the safety of employees engaged in work and prevent the occurrence of disturbances to the

public and the environment.

・Installation of temperature cameras and monitors ・UV antimicrobial treatment ・Securing non-contact conductors

・Wearing white coats ・Wearing gloves, protective glasses,

and masks

・Disinfecting and washing hands ・Cleaning and disinfecting work desks

・Wiping down and disinfecting instruments

General Drainage (Drinking Water, Restrooms, Toilets, etc.) discharged into the public sewage system.

Wastewater from testing rooms is sent to the building’s wastewater treatment facility, treated so that its values

are below those set by public sewage standards, and discharged into the public sewage system.

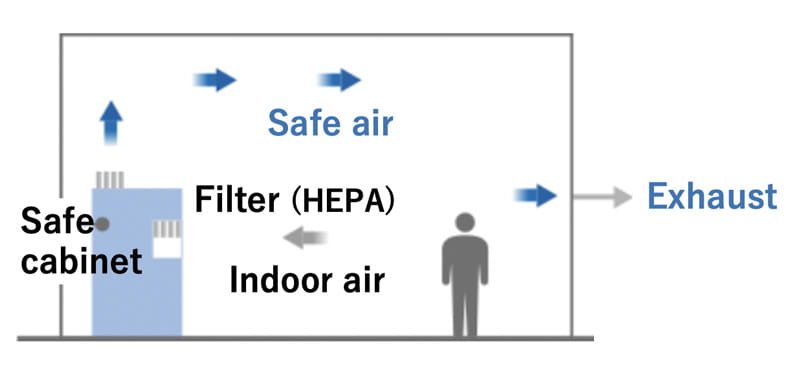

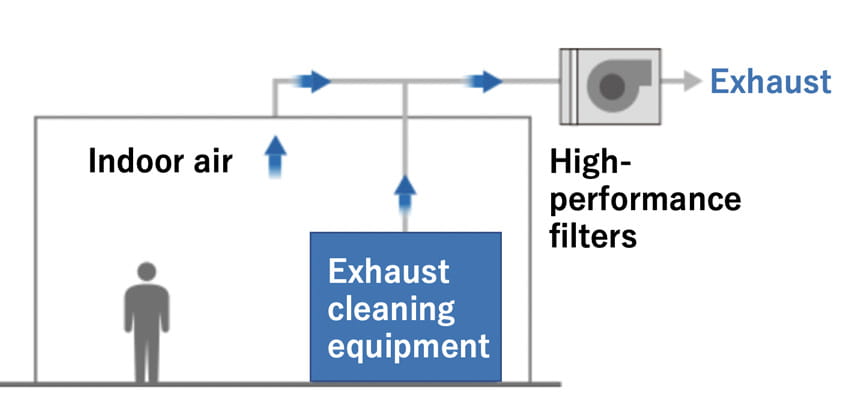

Exhaust measures for laboratories that handle microorganisms and chemical substances, and for laboratories that may generate odors, are as follows: HEPA filters, deodorizing equipment, exhaust cleaning equipment (scrubbers) that also remove chemical substances, etc. are installed depending on the purpose.

Testing is performed in a safe cabinet equipped with a high-performance filter (HEPA), ensuring no dispersal of microorganisms in the testing room or release into the atmosphere.

Exhaust is subject to high-performance filters (HEPA, activated carbon) and exhaust cleaning equipment (scrubbers) that remove the chemical substances.

We separate, store, collect, transport, and dispose of waste properly in accordance with the Waste Management and Public Cleansing Act. Infectious waste, which is the type of waste most frequently generated in the field of clinical testing, is disposed of externally after being sterilized at our in-house waste treatment facility.