I have been involved in the on-site logistics function automation project since the time when the H.U. Bioness Complex was still under construction.

So far, we have been working on the introduction of unmanned transport vehicles (AGVs/AIVs) to the T-Cube (Test Lab Building) and the development of "standard containers" to help deploy test automation.

I came from a different field, and my previous job was as a car manufacturer.

I oversaw creating a mechanism for safely transporting things in factories and warehouses, and I had a strong interest in on-site facility establishment.

Thus, I met the current company which has a warehouse function.

I joined the company in 2017, convinced that although I am not a medical professional, I can contribute in terms of logistics management and facility improvement.

At that time, there were still analog systems such as inventory management in the warehouse, so we insisted that we change the location management to a better system first.

After about two years of work environment improvement activities, I got a call from this new lab project.

Over about two years before it went into operation, we kept on hearing the opinions of people who will use it and consulted with many people within an outside the company, including equipment manufacturers and other cooperating companies, and repeated trials and errors...

It was hard, and at times along the way, I almost cried (laughs).

Looking at the smooth flow of specimens inside and outside of T-Cube, I feel rewarded for our hard work, and I am grateful to all those involved.

This is really a new lab that was the dream of many people.

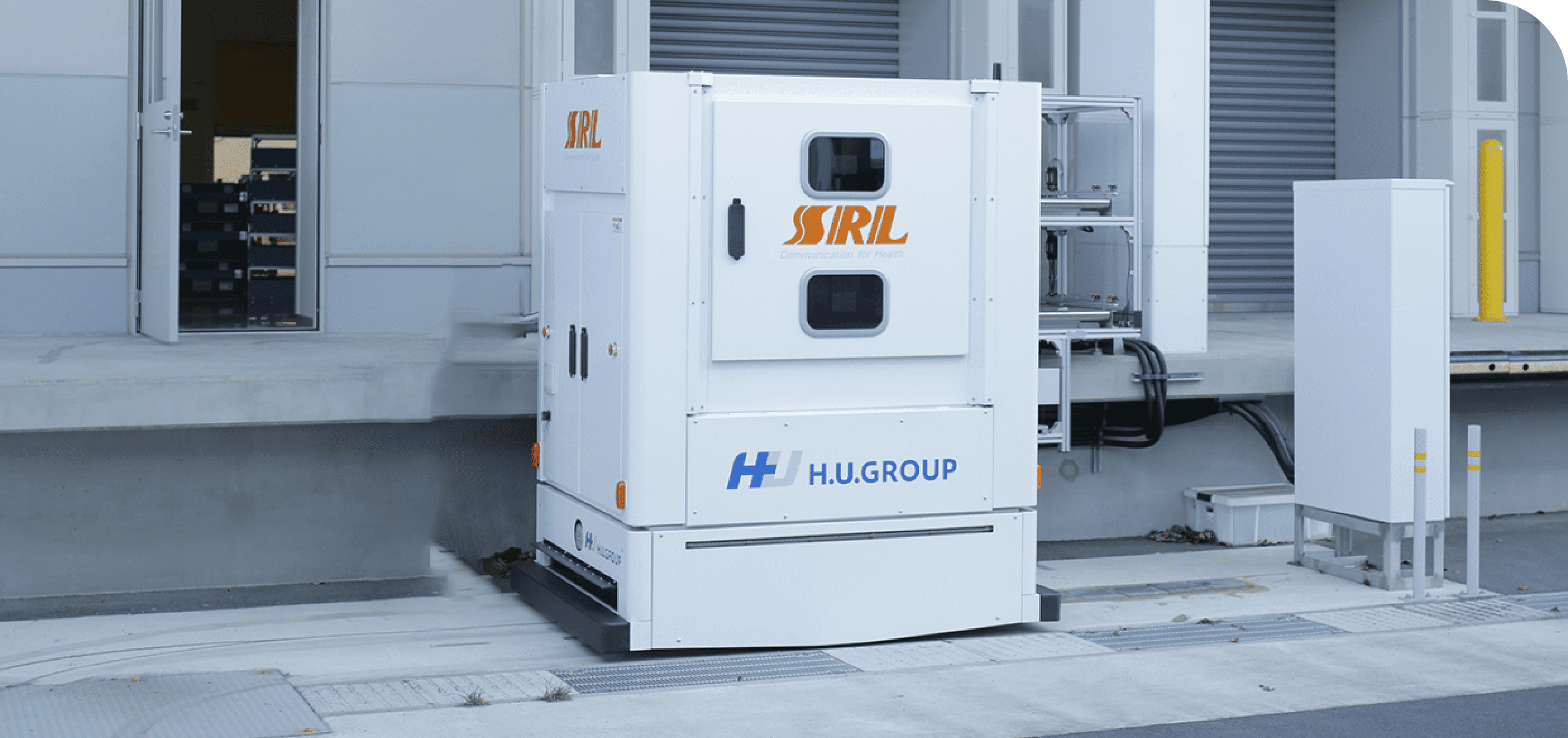

It is a bit too broad to call it a point (laughter), but what I feel my Wow! Point is, are the unmanned AGVs and AIVs driving around the site energetically.

Two outdoor AGVs are currently in operation, and travel strongly between the T-Cube (Test Lab Building) and the T-Cube Annex Building on cold and hot days.

There are 15 indoor AIVs travelling smoothly through the T-Cube.

The T-Cube is a three-story building with each floor measuring 100 m x 150 m.

The quantities of specimens, reagents and materials that are transported every day and the amount of waste that is transported out are enormous.

AIVs have a compact enclosure that makes it easy for them to move around in the laboratory. It smartly lifts a large trolley and runs around the wide T-Cube.

These AIVs are very smart, moving around briskly, stopping and waiting when people are walking nearby, and automatically rerouting so as not to interfere with other AIVs.

AIVs can call the elevator themselves and ride it just by themselves.

Still, I always think about whether they could be further optimized, and I feel still there are a lot of possibilities regarding automation.

There are still issues to be tackled, and by clearing those, I think I can contribute more to people's health and the future of medical care.

Even in the sense that my motivation for work is stimulated in such a way, I always feel that being in a site where AGV and AIV drive around is my Wow! point .